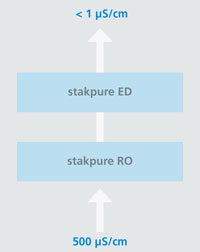

Reverse osmosis and electro-deionisation.

The efficient way to produce and supply pure water on a centralised purified water supply.

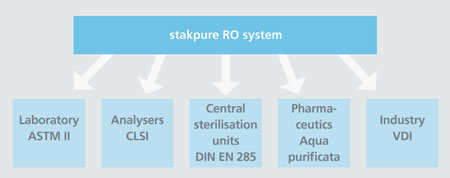

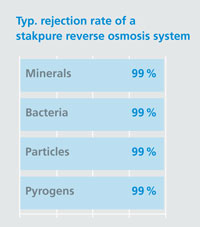

RO systems provide an efficient and cost-effective way of producing a centralised supply of pure water as required in laboratories, health care, pharmaceutical companies and industry.

stakpure reverse osmosis systems are configured to meet specific needs within a capacity range of 20 l/h to 6,000 l/h. This makes it possible to supply individual laboratory and medical systems, floors or even entire buildings. Reliably and always in constantly high quality.

Need purified water of an even higher quality?

In meeting maximum demands on purifying water, an electro-deionisation facility is installed downstream of the RO system to remove any residual minerals. This achieves pure water qualities within a range of 0.067 to 1 μS/cm. Permanent regeneration of the mixed-bed resins in the ED system also produces an extremely high level of water purity without adding chemicals. This rules out the temporary occurrence of impurities and prevents the system from overloading.

Benefits at a glance:

- One central system – space-saving

- No regeneration costs

- No use of chemicals

- Free from particles and bacteria

- High pure water yield

- Modular capacity upgrade

stakpure electro-deionisation ED. For the highest of demands.

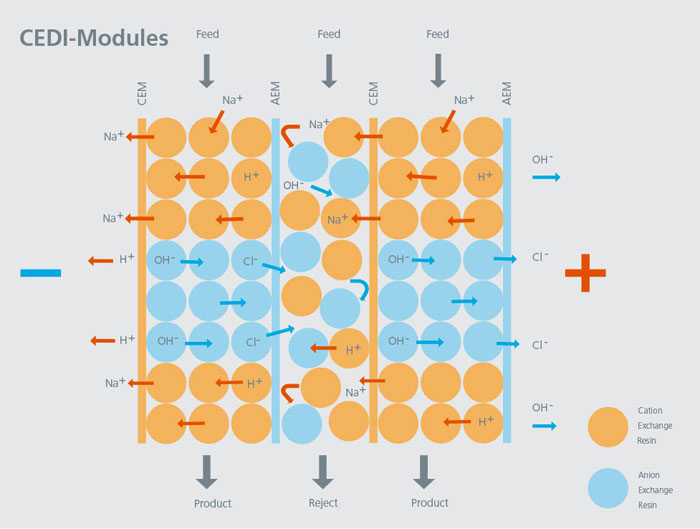

Electro-deionisation combines two processes for producing ultrapure water: the electrodialysis and ion exchanger processes (IEP).

Whereas the conventional ion-exchanger process involves chemically regenerating the resins on a regular basis after longer time use, electro-deionisation continuously regenerates the resins using electric current.

Principle and mode of operation:

With electro-deionisation, water is split into H+ and OH- ions by applying an electric voltage within the cells. This creates a process that continuously regenerates the mixed-bed resins without adding chemicals. Ions are held back on the mixed-bed resins and flushed out through selective membranes that only let anions or cations through. This process rules out any occurrence of impurities and the risk of “impure mixed-bed resins” contaminating the pure water that is produced. Electro-deionisation systems produce a constantly high water quality, making them ideal for supplying pure water to entire building wings in the laboratory (ASTM II), central sterilisation units in clinics (DIN EN 285) as well as for many pharmaceutical and industrial applications.